Home » Applications » Variable Frequency Drive in Hoist and Crane Industries

Variable Frequency Drive in Hoist and Crane Industries

Compensatory externals to aid in starting torque generation for synchronous motors are also basically expense burdens that need not be borne.

The cost of the synchronous motor itself over the asynchronous motor, with increased in frame size, added copper and other materials, is another base reason synch motors are seldom, if ever used in the overhead hoist and crane industry. As far as precise travel and lifting speeds with cranes, variable frequency drives with the hardware and software fairly standard on most variable frequency drives (VFD) designed for the application, is more than adequate. These variable frequency drives not only deliver excellent efficacy and significant energy savings by maintaining very good Volts/Hz/RPM ratios. Utilizing motor speed regulation at 0.5% without an encoder and 0.1% with asynchronous motors, makes the most opted for joint overhead crane control package.

By pre-magnetizing the motor and building up the starting torque level/volts before releasing an electric motor brake, reaching the inertia necessary to lift capacity loads from a suspended point is no problem. Asynchronous motors with the slip factor in them fit the bill with the least amount of expense. It's an extreme comparison, and though it may look, feel, and smell the same, there's little if any incentive to spend what it would take to put a jet engine in a model T, and still wind up with a car. I think it's also interesting you closing your post with regards to wound rotor motors. I wrote an article for OCH and Crane Magazine a couple of years ago regarding the use of wound rotor motors, after seeing an article claiming they were obsolete, and no longer used designs. I design and we build several wound rotor overhead crane controls yearly, as they fit a niche variable frequency drives and squirrel cage motors have a tough, and expensive time trying to occupy. As far as a favorite goes in what I enjoy designing and building most, I do indeed like working with variable frequency drives (VFD), but for me wound rotor systems are a lot more fun.

The cost of the synchronous motor itself over the asynchronous motor, with increased in frame size, added copper and other materials, is another base reason synch motors are seldom, if ever used in the overhead hoist and crane industry. As far as precise travel and lifting speeds with cranes, variable frequency drives with the hardware and software fairly standard on most variable frequency drives (VFD) designed for the application, is more than adequate. These variable frequency drives not only deliver excellent efficacy and significant energy savings by maintaining very good Volts/Hz/RPM ratios. Utilizing motor speed regulation at 0.5% without an encoder and 0.1% with asynchronous motors, makes the most opted for joint overhead crane control package.

By pre-magnetizing the motor and building up the starting torque level/volts before releasing an electric motor brake, reaching the inertia necessary to lift capacity loads from a suspended point is no problem. Asynchronous motors with the slip factor in them fit the bill with the least amount of expense. It's an extreme comparison, and though it may look, feel, and smell the same, there's little if any incentive to spend what it would take to put a jet engine in a model T, and still wind up with a car. I think it's also interesting you closing your post with regards to wound rotor motors. I wrote an article for OCH and Crane Magazine a couple of years ago regarding the use of wound rotor motors, after seeing an article claiming they were obsolete, and no longer used designs. I design and we build several wound rotor overhead crane controls yearly, as they fit a niche variable frequency drives and squirrel cage motors have a tough, and expensive time trying to occupy. As far as a favorite goes in what I enjoy designing and building most, I do indeed like working with variable frequency drives (VFD), but for me wound rotor systems are a lot more fun.

Post a Comment:

You may also like:

Featured Articles

Variable frequency drive for water ...

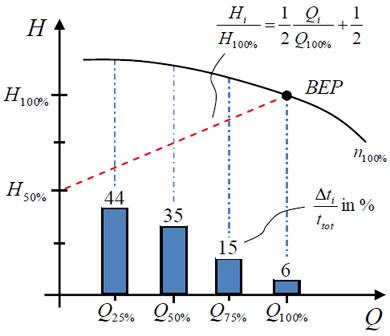

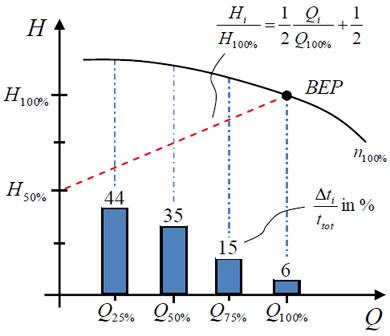

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...

Quantifying the energy efficiency of pump units across markets is a tough task: These units mostly consist of rotodynamic pumps ...Single VFD for Multiple Motors

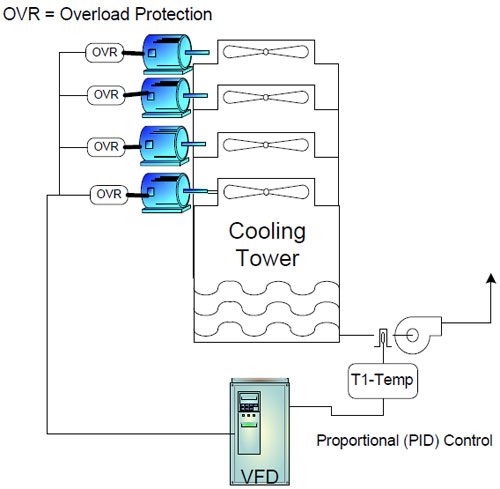

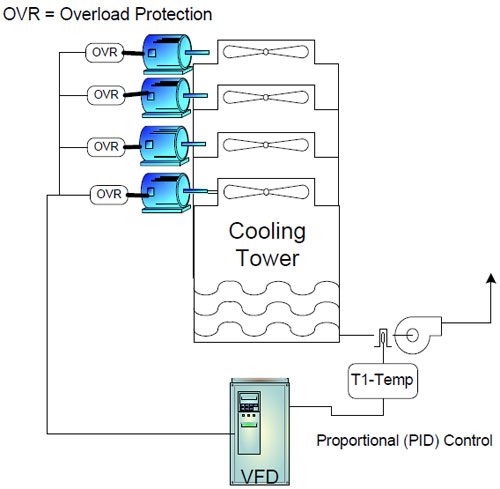

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...

A single variable frequency drive (VFD) may control 2 or 3 motors at a time, multiple motors control is usually done because of ...Select a right Variable Frequency Drive

Before selecting a Variable Frequency Drive (VFD) for an existing electric motor, it's important to know the purpose and ...

Before selecting a Variable Frequency Drive (VFD) for an existing electric motor, it's important to know the purpose and ...

Before selecting a Variable Frequency Drive (VFD) for an existing electric motor, it's important to know the purpose and ...

Before selecting a Variable Frequency Drive (VFD) for an existing electric motor, it's important to know the purpose and ...VFD on air compressor considerations

When installing a variable frequency drive is that the air ends (i.e. impellers) are usually custom made for the air compressor. ...

When installing a variable frequency drive is that the air ends (i.e. impellers) are usually custom made for the air compressor. ...

When installing a variable frequency drive is that the air ends (i.e. impellers) are usually custom made for the air compressor. ...

When installing a variable frequency drive is that the air ends (i.e. impellers) are usually custom made for the air compressor. ...

Variable Frequency Drives control AC motor for energy savings by adjustable speed, for short VFD, also named variable speed drives and frequency inverter.