Surge testing in motor manufacturing

I have used surge testing since 1989 in motor manufacturing, motor repair shops and for field testing of motors. I am a big fan of surge testing and have performed over voltage surge tests on 10,000s of motors. It is the only test which can detect weakened insulation between phases or coils in a connected winding. It is a standard test performed by every reputable motor manufacturer and motor repair shop in the world. And it is an excellent test for verifying insulation in the field.

Surge testing, like hipot testing, can be performed at voltages greater than motor nameplate voltage. It is common to perform hipot and surge testing at voltages well above nameplate voltage to verify that an insulation system can withstand the voltage transients and other mechanical stresses which occur at start up. The recommended field hipot and surge test voltages are 40% or more lower than voltages used by manufacturers and rewinders.

Over voltage tests stress the insulation system. If the insulation system is weak, an arc will occur and may significantly damage the winding. If an arc does not occur, an immeasurably small amount of damage may occur to the winding if partial discharge is generated during the test. But, the partial discharge damage from a few minutes of testing is insignificant in the life of the motor. Thus the question is whether I am damaging motors when I over voltage hipot or surge test in the field. The answer is yes, but, immeasurably.

And it is better to perform these tests than to not perform them. Knowing that the insulation system is in good condition and should operate satisfactorily till the next outage makes over voltage testing worthwhile most of the time in my opinion. You have to do your own financial analysis to determine if the benefits of these tests outweigh the risks of an unplanned outage in your situation.

There is a whole protocol to over voltage testing which you need to learn to avoid damaging an insulation system which could be repaired without a rewind. Don't over voltage test if the IR or PI are low indicating the presence of moisture or surface contaminants. Don't perform over voltage testing unless you have the opportunity to repair or replace a bad motor when you find one. Otherwise you may be blamed (by the less knowledgeable) for causing the problem by over voltage testing (even though the motor would have failed fairly soon on its own regardless of whether you did the test).

I can attest that I have never failed a motor that was not already close to failure or measurably shortened the life of a motor by doing these tests in the field. And I have identified motors with damaged insulation which were okay according to the low voltage tests(winding resistance, inductance, capacitance, IR, PI, etc). I recommend that you learn about the hipot and surge tests and use them wisely. You will have a better motor PdM program if you do.

Surge testing, like hipot testing, can be performed at voltages greater than motor nameplate voltage. It is common to perform hipot and surge testing at voltages well above nameplate voltage to verify that an insulation system can withstand the voltage transients and other mechanical stresses which occur at start up. The recommended field hipot and surge test voltages are 40% or more lower than voltages used by manufacturers and rewinders.

Over voltage tests stress the insulation system. If the insulation system is weak, an arc will occur and may significantly damage the winding. If an arc does not occur, an immeasurably small amount of damage may occur to the winding if partial discharge is generated during the test. But, the partial discharge damage from a few minutes of testing is insignificant in the life of the motor. Thus the question is whether I am damaging motors when I over voltage hipot or surge test in the field. The answer is yes, but, immeasurably.

And it is better to perform these tests than to not perform them. Knowing that the insulation system is in good condition and should operate satisfactorily till the next outage makes over voltage testing worthwhile most of the time in my opinion. You have to do your own financial analysis to determine if the benefits of these tests outweigh the risks of an unplanned outage in your situation.

There is a whole protocol to over voltage testing which you need to learn to avoid damaging an insulation system which could be repaired without a rewind. Don't over voltage test if the IR or PI are low indicating the presence of moisture or surface contaminants. Don't perform over voltage testing unless you have the opportunity to repair or replace a bad motor when you find one. Otherwise you may be blamed (by the less knowledgeable) for causing the problem by over voltage testing (even though the motor would have failed fairly soon on its own regardless of whether you did the test).

I can attest that I have never failed a motor that was not already close to failure or measurably shortened the life of a motor by doing these tests in the field. And I have identified motors with damaged insulation which were okay according to the low voltage tests(winding resistance, inductance, capacitance, IR, PI, etc). I recommend that you learn about the hipot and surge tests and use them wisely. You will have a better motor PdM program if you do.

Post a Comment:

You may also like:

Featured Articles

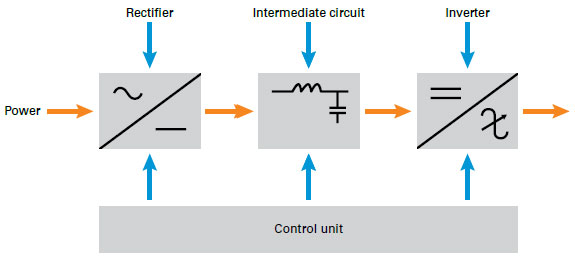

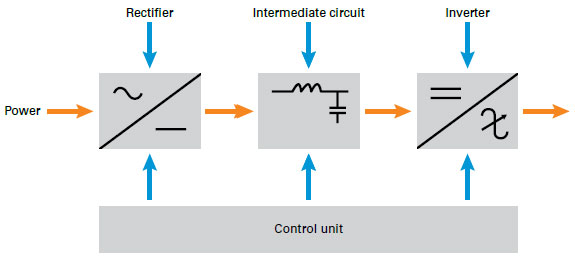

PWM Variable Frequency Drive ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...Variable Frequency Drive Working ...

This guideline discusses variable frequency drive (VFD) basic working principle and how installing variable frequency drives in ...

This guideline discusses variable frequency drive (VFD) basic working principle and how installing variable frequency drives in ...

This guideline discusses variable frequency drive (VFD) basic working principle and how installing variable frequency drives in ...

This guideline discusses variable frequency drive (VFD) basic working principle and how installing variable frequency drives in ...

Variable Frequency Drives control AC motor for energy savings by adjustable speed, for short VFD, also named variable speed drives and frequency inverter.