Can a VFD driven motor run at zero speed?

It has always been acceptable to be able to reduce the speed of a variable torque application to near zero speeds. I continue to get into these arguments on startups with inexperienced commissioning people. If it is a constant-torque application, (i.e. positive displacement pumps or compressors) taking the speed to near zero is a very big NO-NO... But fans and centrifugal pumps are not constant-torque applications. I normally recommend to set the bottom end of the speed to 10%, but theoretically they can go down to virtually "zero". Most of the concerns are always that the motor will overheat, but due to the nature of variable torque applications, the heat produced is also variable. We all know (at least we hope so...) that the heat dissipated is directly proportional to the surface area of the motor frame.

Thirty years ago when we were first seeing 30 hp variable frequency drive (VFD) the size of a refrigerator (and now the size of a brief case), and there was no such thing as a severe duty motor, and it was an absolute TABOO to use a variable frequency drive (VFD) for variable speed. Actually for variable-torque applications, severe duty motors are not required... You are just wasting money for the severe duty motor!

When using single stage pumps, the pump speed is critical, and the pump curve should be verified. But when using submersible pumps, these are typically multi-stage (maybe 15+ stages) and can be reduced much lower in speed. With centrifugal pumps, of course efficiency drops off. Fans have a much lower threshold as where they become ineffective. We have done many pump and fan variable drive applications in the last 30 years, and turning the speed down has never been a problem... With constant-torque applications, it is not recommended to go below 30% even when using a severe duty motor.

The facts be known, in variable torque service the heat produced by the motor are significantly less than a standard motor running at rated hp. Standards like this are a result of the lack of research into reality written by individuals with the lack of practical experience. Hence the requirement to use inverter duty motors in this application are a waste of money. I have proven this time and time again over the last 30+ years.

Thirty years ago when we were first seeing 30 hp variable frequency drive (VFD) the size of a refrigerator (and now the size of a brief case), and there was no such thing as a severe duty motor, and it was an absolute TABOO to use a variable frequency drive (VFD) for variable speed. Actually for variable-torque applications, severe duty motors are not required... You are just wasting money for the severe duty motor!

When using single stage pumps, the pump speed is critical, and the pump curve should be verified. But when using submersible pumps, these are typically multi-stage (maybe 15+ stages) and can be reduced much lower in speed. With centrifugal pumps, of course efficiency drops off. Fans have a much lower threshold as where they become ineffective. We have done many pump and fan variable drive applications in the last 30 years, and turning the speed down has never been a problem... With constant-torque applications, it is not recommended to go below 30% even when using a severe duty motor.

The facts be known, in variable torque service the heat produced by the motor are significantly less than a standard motor running at rated hp. Standards like this are a result of the lack of research into reality written by individuals with the lack of practical experience. Hence the requirement to use inverter duty motors in this application are a waste of money. I have proven this time and time again over the last 30+ years.

Post a Comment:

You may also like:

Featured Articles

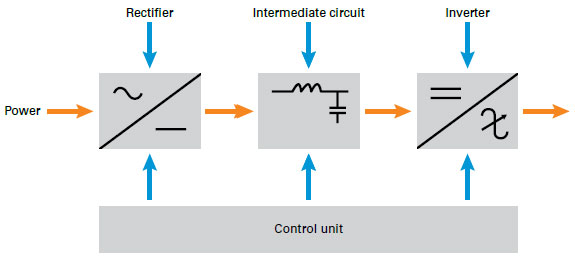

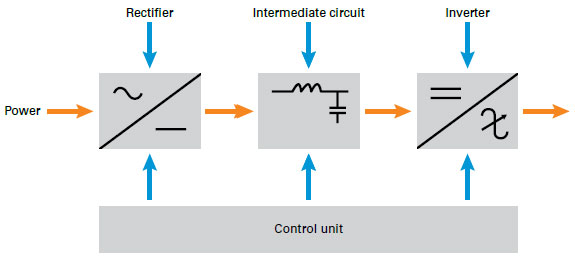

Variable Frequency Drive Working ...

This guideline discusses variable frequency drive (VFD) basic working principle and how installing variable frequency drives in ...

This guideline discusses variable frequency drive (VFD) basic working principle and how installing variable frequency drives in ...

This guideline discusses variable frequency drive (VFD) basic working principle and how installing variable frequency drives in ...

This guideline discusses variable frequency drive (VFD) basic working principle and how installing variable frequency drives in ...PWM Variable Frequency Drive ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Pulse Width Modulation (PWM) voltage source variable frequency drives (VFD) presently comprehend the most used equipments to feed ...

Variable Frequency Drives control AC motor for energy savings by adjustable speed, for short VFD, also named variable speed drives and frequency inverter.