Variable Frequency Drive for cost and energy saving

Talking to any VFD suppliers' sales and they'll provide you with a similar pitch for their wares. By installing a variable frequency drive that regulates the speed and/or torque output of your electric motor-driven plant, they say, you'll save the costs and energy – within a few of months. Indeed, the investment will pay for itself many times over before the motor's end of life.

Yet ask plant engineers and managers, and while there are certainly zealots who insist they have proved VFD's potency time and again, there are also sceptics who point to hidden costs and limitations. Others suggest that high-efficiency motors are a safe bet for improving energy performance, especially given the widely acknowledged problem with existing motors of over-sizing. And there are others again who contend that motors and VFDs are not the only games in town when it comes to motor-driven systems.

This matters. Electric motors are widely believed to be responsible for about two thirds of the China industrial energy consumption and around a quarter of total Chinese electricity output. Just as important, the purchase price of a motor typically represents only 2—3% of the total cost – the rest being the lifetime cost of electrical energy. So, on the one hand, there can be no doubt that there is a huge amount to go for, and, on the other, the laser focus should be on running costs. The issue is where to prioritize, and the truth is that plant engineers need to adopt a holistic approach.

That said, there is no contest. Variable frequency drive offers by far and away the biggest potential for cost and emissions savings – and that's on everything from pumps and fans to HVAC systems.

Gozuk supports higher efficiency motors as part of the solution to energy saving, but if that's your only focus, you'll achieve limited improvement. Typically, IE2 [roughly equating to earlier EEf 1] motors consume maybe 2—3% less energy than older standard motors, while premium IE3 units may be 3—5% better. But variable frequency drive control can deliver double digit improvements of 30—50%, or even higher, by turning down rotational speed and torque at source, or even switching motors off when they're not required.

While control is the key to serious energy savings, issues such as hours running and the extent to which a motor might be turned down or switched off without impacting the process, are also important. Any energy-saving improvement project should consider the whole driven system, if only because there are other factors too that invariably offer incremental, but quick and often cheap wins.

The three clear opportunities: power transmissions; antique motor technology; and automatic controls. Vee-belt drives are often poorly set up and technicians get away with it because they're very forgiving. But if they're not aligned and tensioned properly there's excessive frictional losses and pulley wear, adding that modern belts enable greater tension, reduced slip and longer life.

As for old technology, Maher lists slip ring motors, mechanical-, belt- and hydraulic-variators, most of which are inherently inefficient and poorly documented – meaning that upgrading to new motors is almost certainly sensible. Incidentally, we also suggests that where re-sizing is being considered, remember that many motors are more energy efficient at three quarters load than fully loaded, so don't be too enthusiastic.

Then controls: and Maher's observation is that, while variable frequency drives tend to be thought of as the first port of call, sometimes there are simpler options. For example, with conveyors, if the objective is on/off only, an optical sensor and switching on clear conveyor countdown may well be enough.

Returning to variable frequency drives, however, the biggest barriers to uptake that could transform industry's energy efficiency are twofold. First, businesses' short termism means that many are reluctant to invest at all, no matter how robust the proposition. They prefer instead to go the cost-cutting route. And second, purchasing managers' unflinching focus on how much motor systems cost to buy, rather than to run – in spite of the proven importance of the latter – forces exclusion of any add-ons.

Energy saving is making yourself more competitive in preparation for growth, cost saving is not spending but, instead, laying people off and reducing the business' ability to grow. It makes no more sense than purchasing looking only at the cost line.

On this point, as long as the market works by machine suppliers competing on price alone, nothing is likely to improve. One way to change the situation is to insist that quotations include lifetime costs with estimated long-term savings. Given that break-even is generally less than a year for a variable frequency drive installed on motors above 5kW in a variable torque application, the approach would be compelling.

Currently, include all motors above 375kW, ATEX motors for use in notified hazardous areas and existing motors now coming up for repair or re-manufacture. Can that be right? Yes, large motors tend to be more efficient, but they consume greater energy so even a small percentage improvement could make a substantial difference. Meanwhile, savings on motors running at full speed in hazardous area applications must surely be persuasivein the long term. And where is the sense in allowing old, inefficient motors simply to be renewed? It's bad for the environment, the economy and, in the end, the plant's own finances.

Yet ask plant engineers and managers, and while there are certainly zealots who insist they have proved VFD's potency time and again, there are also sceptics who point to hidden costs and limitations. Others suggest that high-efficiency motors are a safe bet for improving energy performance, especially given the widely acknowledged problem with existing motors of over-sizing. And there are others again who contend that motors and VFDs are not the only games in town when it comes to motor-driven systems.

This matters. Electric motors are widely believed to be responsible for about two thirds of the China industrial energy consumption and around a quarter of total Chinese electricity output. Just as important, the purchase price of a motor typically represents only 2—3% of the total cost – the rest being the lifetime cost of electrical energy. So, on the one hand, there can be no doubt that there is a huge amount to go for, and, on the other, the laser focus should be on running costs. The issue is where to prioritize, and the truth is that plant engineers need to adopt a holistic approach.

That said, there is no contest. Variable frequency drive offers by far and away the biggest potential for cost and emissions savings – and that's on everything from pumps and fans to HVAC systems.

Gozuk supports higher efficiency motors as part of the solution to energy saving, but if that's your only focus, you'll achieve limited improvement. Typically, IE2 [roughly equating to earlier EEf 1] motors consume maybe 2—3% less energy than older standard motors, while premium IE3 units may be 3—5% better. But variable frequency drive control can deliver double digit improvements of 30—50%, or even higher, by turning down rotational speed and torque at source, or even switching motors off when they're not required.

While control is the key to serious energy savings, issues such as hours running and the extent to which a motor might be turned down or switched off without impacting the process, are also important. Any energy-saving improvement project should consider the whole driven system, if only because there are other factors too that invariably offer incremental, but quick and often cheap wins.

The three clear opportunities: power transmissions; antique motor technology; and automatic controls. Vee-belt drives are often poorly set up and technicians get away with it because they're very forgiving. But if they're not aligned and tensioned properly there's excessive frictional losses and pulley wear, adding that modern belts enable greater tension, reduced slip and longer life.

As for old technology, Maher lists slip ring motors, mechanical-, belt- and hydraulic-variators, most of which are inherently inefficient and poorly documented – meaning that upgrading to new motors is almost certainly sensible. Incidentally, we also suggests that where re-sizing is being considered, remember that many motors are more energy efficient at three quarters load than fully loaded, so don't be too enthusiastic.

Then controls: and Maher's observation is that, while variable frequency drives tend to be thought of as the first port of call, sometimes there are simpler options. For example, with conveyors, if the objective is on/off only, an optical sensor and switching on clear conveyor countdown may well be enough.

Returning to variable frequency drives, however, the biggest barriers to uptake that could transform industry's energy efficiency are twofold. First, businesses' short termism means that many are reluctant to invest at all, no matter how robust the proposition. They prefer instead to go the cost-cutting route. And second, purchasing managers' unflinching focus on how much motor systems cost to buy, rather than to run – in spite of the proven importance of the latter – forces exclusion of any add-ons.

Energy saving is making yourself more competitive in preparation for growth, cost saving is not spending but, instead, laying people off and reducing the business' ability to grow. It makes no more sense than purchasing looking only at the cost line.

On this point, as long as the market works by machine suppliers competing on price alone, nothing is likely to improve. One way to change the situation is to insist that quotations include lifetime costs with estimated long-term savings. Given that break-even is generally less than a year for a variable frequency drive installed on motors above 5kW in a variable torque application, the approach would be compelling.

Currently, include all motors above 375kW, ATEX motors for use in notified hazardous areas and existing motors now coming up for repair or re-manufacture. Can that be right? Yes, large motors tend to be more efficient, but they consume greater energy so even a small percentage improvement could make a substantial difference. Meanwhile, savings on motors running at full speed in hazardous area applications must surely be persuasivein the long term. And where is the sense in allowing old, inefficient motors simply to be renewed? It's bad for the environment, the economy and, in the end, the plant's own finances.

Post a Comment:

You may also like:

Featured Articles

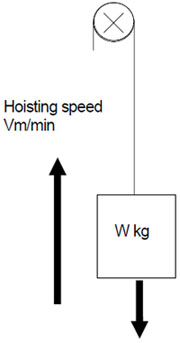

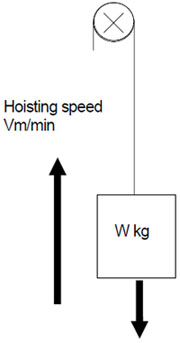

Variable Frequency Drive Sizing

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...

Before selecting the size of a variable frequency drive (VFD), it is necessary to generally know the working environment, the ...Variable Frequency Drive Basic Safety ...

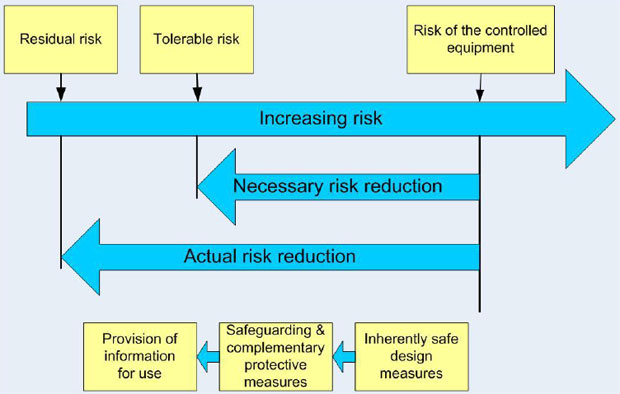

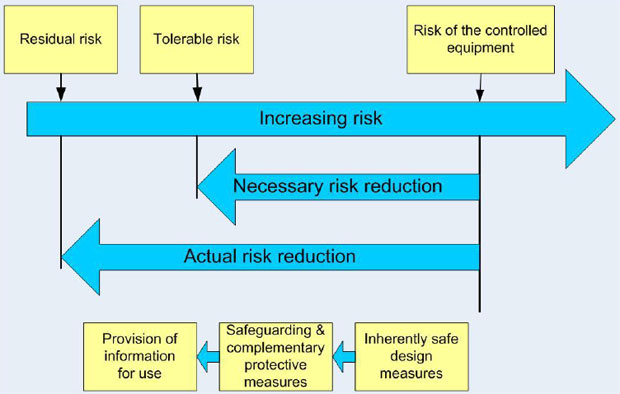

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

This paper provides guidelines on functional safety considerations when selecting and integrating a variable frequency drive ...

Variable Frequency Drives control AC motor for energy savings by adjustable speed, for short VFD, also named variable speed drives and frequency inverter.